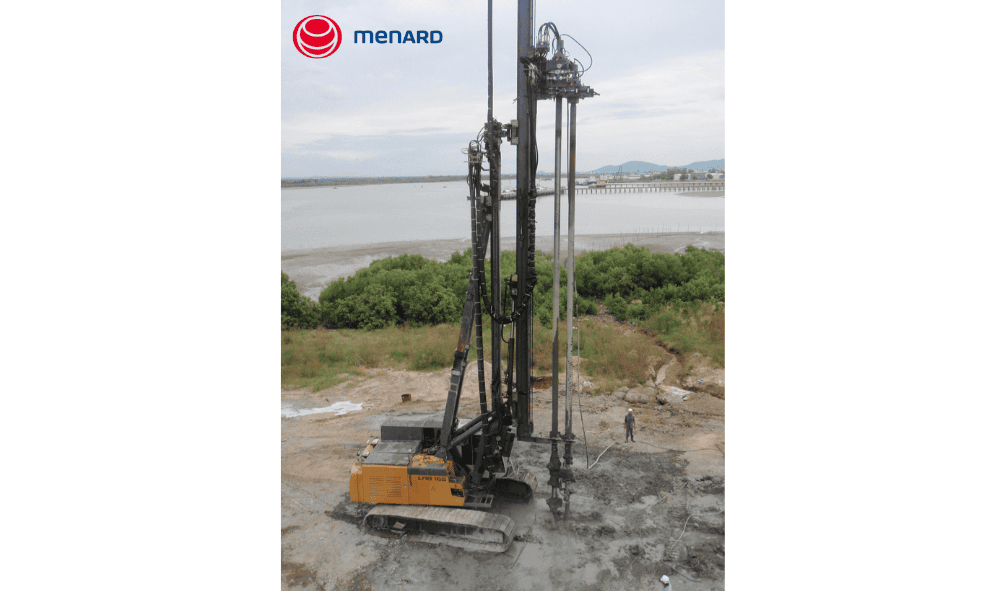

Deep Soil Mixing (DSM) involves the injection of binder agents to mix with the soil and form columns to reinforce the ground.

The method of the Deep Soil Mixing column was invented in Japan in 1970s and since then it has been gaining the increasing popularity all over the world as a ground improvement method to stabilise soils with low bearing capacity.

Presentation and key elements

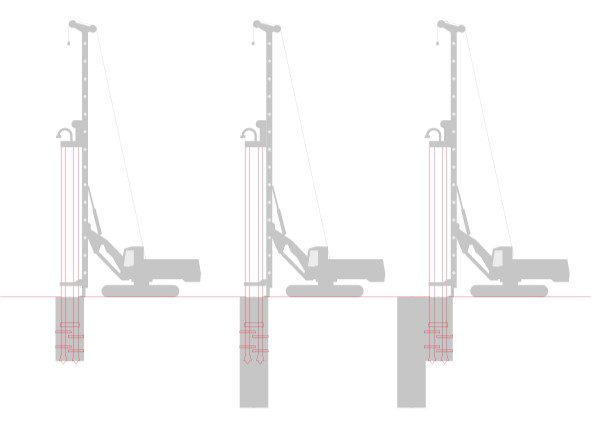

Deep Soil Mixing Animation

Why choose Menard Asia for DSM?

Our experience in ground improvement solutions makes us a trusted partner in providing effective and efficient Deep Soil Mixing (DSM) services.

Menard Asia delivers tailored solutions to enhance soil stability, improve load-bearing capacity, and mitigate the risks of soil liquefaction, ensuring the longevity and safety of your projects.

1. Proven Expertise in Deep Soil Mixing Method

With decades of experience, Menard has developed a strong reputation in implementing the DSM technique, helping clients achieve better foundation stability, even in challenging soil conditions like silty sand or soft clay.

2. Comprehensive Ground Improvement Solutions

Menard Asia offers a complete suite of ground improvement services, ensuring that every aspect of your project is handled with expertise. From design to execution, we provide an end-to-end solution that adapts to your project’s needs.

3. Customized Deep Soil Mixing Services for Your Project

We understand that every project is unique. That’s why we tailor our DSM services to meet your specific ground conditions, load requirements, and project goals, ensuring optimal results.

Types of Deep Soil Mixing Techniques We Offer

Benefits of Choosing Our Deep Soil Mixing Services

Menard Asia’s Brochure

Get Started with Menard Asia’s Deep Soil Mixing Services

Reach out to our team for a detailed consultation on how Deep Soil Mixing can benefit your project and a tailored quotation based on your project’s requirements. (For FREE!)