Jet Grouting (JG) uses high velocity jet of grout to destroy the soil structure and simultaneously mix cement grout into the in-situ soil to form inclusions.

Jet grouting method – is used to improve soil strength parameters and at the same time to create an impervious layer.

What is Jet Grouting?

Jet grouting is a ground improvement and reinforcement process that uses high-pressure jet of grout to destroy the soil structure and simultaneously mix cement grount into the in-situ soil to form soil concrete. The result is a solidified column that increases strength, reduces permeability, and supports structures built on soft or unstable ground.

Jet grouting can be applied to most types of soil, from soft clay to sand and gravel. It is highly effective to hard soils or rock containing anomalies such as clayey or karstic alterations. Jet grouting process is suitable to work in areas where space is limited and/or excavation is not possible.

How Jet Grouting Works

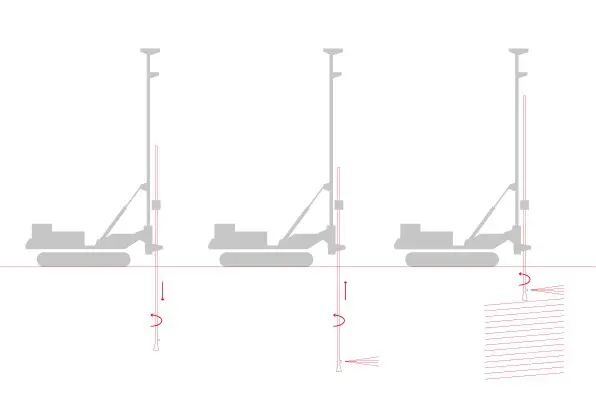

Jet grouting involves three key actions performed in sequence:

1. Soil Disruption

A fluid is injected using high-pressure grout into the ground through a rotating drill rod to break up the soil structure.

2. Spoil Extraction

The disrupted soil, mixed with grout, is partially displaced and rises to the surface. This slurry is removed regularly to keep the platform clean.

3. In-Situ Mixing

As the drill rod is slowly withdrawn, the grout mixes with the loosened soil, forming a solidified soil-cement mixture column.

The equipment is composed of a grout plant, which includes a cement silo, mixing plant, and high-pressure pump. These are connected via flexible high-pressure hoses to a drilling rig.

Jet Grouting Equipment and Components

The equipment is composed of a grout plant, which includes a cement silo, mixing plant, and high-pressure pump. These are connected via flexible high-pressure hoses to the drilling rig.

1. Grout Plant

Includes storage silos, mixers, and high-pressure pumps for continuous operation.

2. Drilling Rig

Equipped with rotating rods and specialized nozzles to inject grout with high energy.

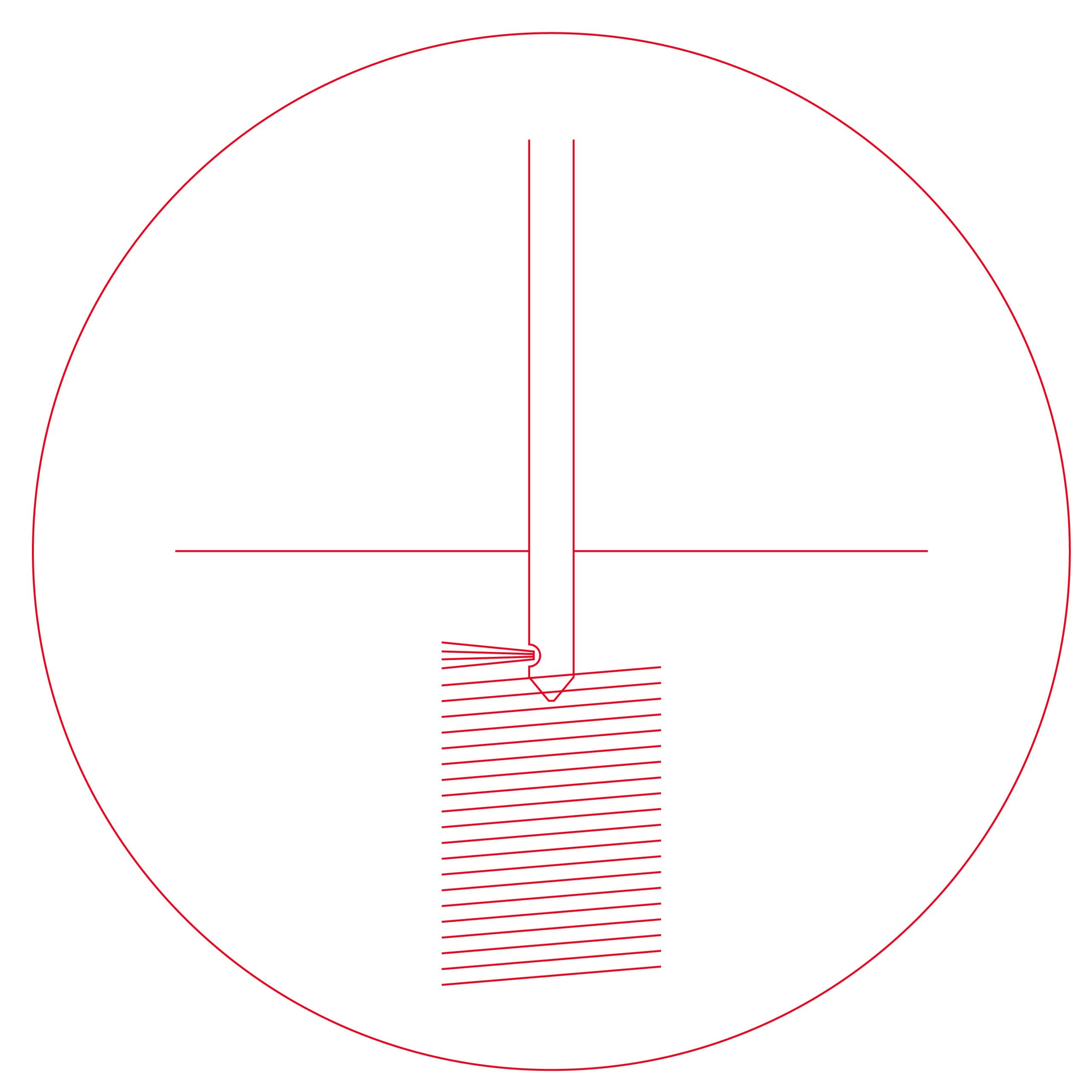

3. Injection Nozzles

Small diameter outlets (1 to 10 mm) located at the rod tip, designed for precise high-pressure delivery.

4. Drilling Rods

Selected based on desired column diameter and soil conditions.

5. Spoil Handling

Spoils are regularly extracted from the surface to maintain safe and clean working conditions.

Each grout column starts with a guide hole, approximately 10 cm in diameter, drilled to the target depth.

Grout is then injected at 200 to 400 liters per minute and mixed with soil to form a solidified mass. As the rod is withdrawn, the column forms upward in a continuous motion.

Jet Grouting Equipment and Components

Jet grouting can be customized for different ground conditions and column geometries using one of the following systems:

Single Jet Grouting

Grout alone is injected at high pressure through a single nozzle. It combines soil breakdown, spoil removal, and grout mixing in one step.

Double Jet Grouting

Grout is injected alongside a high-pressure air jet. The air jet surrounds the grout stream, increasing its reach and mixing efficiency. The air-lifting effect improves spoil extraction and allows for larger diameter columns than the single jet method.

Triple Jet Grouting

Three independent jets (water, air, and grout) are used. Water and air jets loosen the soil under high pressure, and grout is injected separately into the liquefied soil.

Applications of Jet Grouting

Jet grouting is used to improve soil for various structures in urban, industrial, and infrastructure projects.

1. Urban and Confined Sites

Jet grouting is ideal for city centers and congested areas where space is tight, and nearby structures are sensitive to vibration. It reinforces the ground under buildings, roads, and tunnels.

2. Tunneling and Underground Works

Creates groundwater cut-off walls and stabilizes the soil around excavation shafts and tunnel portals. It is commonly used for station boxes and cross passages in metro and underground systems.

3. Hydraulic Structures and Water Control

Forms low-permeability barriers to control seepage in dams, levees, and embankments. It also strengthens foundations near rivers or coastal zones.

4. Transport and Infrastructure

Improves the foundation for railways, roads, airport runways, and bridge abutments. Jet grouting helps maintain alignment and support heavy loads in poor soil conditions.

5. Seismic Zones

Jet grouting reduces liquefaction risks and improves lateral stability in seismic-prone regions. It increases soil cohesion and strength to withstand earthquake loads.

Key Benefits of Jet Grouting

Applicable to a Wide Range of Soils

Jet Grouting is highly adaptable and can be applied to most soil types, from soft clay to sand and gravel.

Ideal for Limited Access Areas

With equipment that operates in constrained environments, Jet Grouting is well-suited for areas with restricted headroom or challenging access conditions, such as under existing structures or in urban settings.

Effective Ground Waterproofing

The injected grout, typically a mix of water and cement, forms a low-permeability, load-bearing mass. Bentonite can be added to further enhance waterproofing when needed.

Reinforces Deep, Inaccessible Layers

Since this process involves small-diameter boreholes, Jet Grouting can penetrate through dense surface layers to treat deeper, softer soils that require reinforcement for structural stability.

Supports Structural Loads Efficiently

Jet Grouting improves bearing capacity significantly, achieving allowable pressures between 0.2 to 0.4 MPa under foundation blocks (footings, strip foundations, or mats), depending on soil conditions at service limit state (SLS).

Why Choose Menard Asia for Jet Grouting

Menard Asia provides complete jet grouting services—from design and equipment to installation and verification.

Expertise Across Soil Conditions

Our engineers select the appropriate ground improvement method based on soil analysis and project specifications. We deliver jet grouting solutions even in difficult and sensitive conditions.

Advanced Equipment

Menard Asia operates jet grouting rigs with high-capacity pumps, digital monitoring, and safety systems. Our setups meet international quality standards and local regulations.

End-to-End Service

We manage every phase:

- Soil investigation

- Grouting design and performance modeling

- Equipment mobilization and site logistics

- Column installation, and post-grouting testing

Download Our Jet Grouting Brochure

Get the full breakdown of our jet grouting solutions.

📩 Download the Brochure to explore:

- Technical data and grout types

- Column dimensions and specifications

- Case studies and construction methods

Request a Quote

Need a jet grouting solution for your site?

📩 Request a Quote and get:

- Site-specific recommendations

- Column sizing and layout plans

- Timeline and pricing estimates

- Technical support from Menard Asia’s geotechnical team

Frequently Asked Questions (FAQ)

Jet Grouting can theoretically be used in any type of soft soils, from soft clay to sand and gravel. However, the technique is not suited to coarse gravel or soils with underground water flow. For ground improvement projects, it is typically used under uniform loading (e.g., storage platforms, embankments, slabon-grade) or under localized loads (e.g., building footings, bridge piers).

The choice between single, double, or triple jet grouting depends on the soil type, strength requirements, and target column size. For cohesive soils, single jet is often sufficient. For sandy or denser soils, double or triple jet allows better mixing and larger diameter columns.

3. How do jet grouting columns compare to traditional piles?

Jet grouting creates in-place soil-cement columns that improve ground properties but are not structural piles. They are often used as ground treatment rather than primary load-bearing elements. For load transfer, jet grouting can be combined with shallow foundations or slabs.

4. Can jet grouting be used for water control?

Yes. Jet grouting can form low-permeability barriers that block or redirect groundwater flow. This is useful in excavation pits, tunneling, or areas near water bodies. Bentonite may be added to the mix to improve impermeability.

5. Can jet grouting be performed in tight or low-clearance spaces?

Yes. Jet grouting rigs can be adapted for compact or low-height areas. This makes them ideal for basement projects, tunnel zones, or renovations where overhead space is limited.

Yes. Jet grouting can form low-permeability barriers that block or redirect groundwater flow. This is useful in excavation pits, tunneling, or areas near water bodies. Bentonite may be added to the mix to improve impermeability.

Yes. Jet grouting rigs can be adapted for compact or low-height areas. This makes them ideal for basement projects, tunnel zones, or renovations where overhead space is limited.

Our projects

Laos | Truong Son Wind Power Plantirfan2025-09-29T15:15:07+07:00

Philippines | Kalayaan 2 Wind Power Projectirfan2025-06-02T15:35:49+07:00

Bangladesh | Industrial Facility in Trishal, Mymensinghirfan2025-05-31T08:52:02+07:00

Cambodia | Bassac Lane Restaurant, Phnom Penhirfan2025-05-31T08:56:27+07:00

Cambodia | Sihanoukville Port Expansion with Vibro Compactionirfan2025-05-20T09:01:34+07:00

Cambodia | Office Building in Bavetirfan2025-05-16T09:20:40+07:00