Quality Assurance and Control Process in Controlled Modulus Column (CMC) Rigid Inclusions

When it comes to building strong structures, ensuring the quality of the foundation is essential. That’s where quality assurance (QA) and quality control (QC) come into play. These processes help make sure that everything from the materials used to how the work is done meets the highest standards.

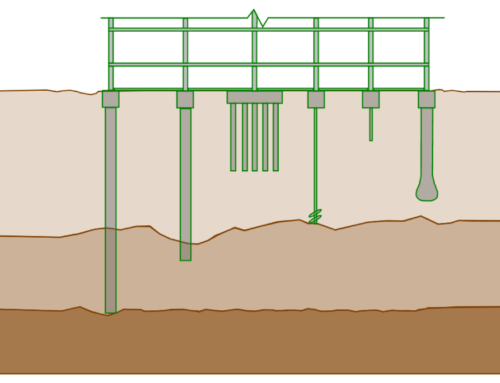

At Menard, we offer a variety of ground improvement solutions, each designed to address specific challenges in foundation engineering. One of our most widely used techniques is the Controlled Modulus Column (CMC) rigid inclusions, which is particularly effective in projects requiring improved soil strength and stability.

In this article, we will walk you through the quality assurance (QA) and quality control (QC) process that ensures the installation of CMC rigid inclusions meets the highest standards, including material testing, real-time monitoring and field verification tests.

The QA/QC Process for Controlled Modulus Column (CMC) Rigid Inclusions

1. Prior to Construction

Before any CMC rigid inclusion project begins, we make sure the materials are up to the task. One of the first steps is checking the grout mix.

Grout mix is the substance used to create the columns. The grout mix design is thoroughly reviewed by the engineer, and it must meet the minimum compressive strength specified in the project design requirements. Additionally, the grout must maintain the necessary pumpability to be safely and effectively pumped through the installation equipment.

2. During the Execution

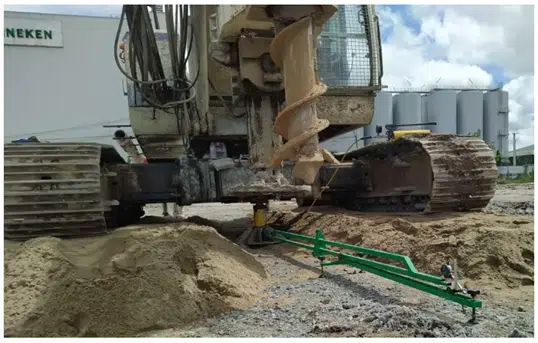

Once construction begins, every batch of concrete delivered to the site undergoes a basic slump test, and samples are collected for compressive strength testing. This ensures that the concrete meets the minimum design requirements and specifications for the CMC rigid inclusions.

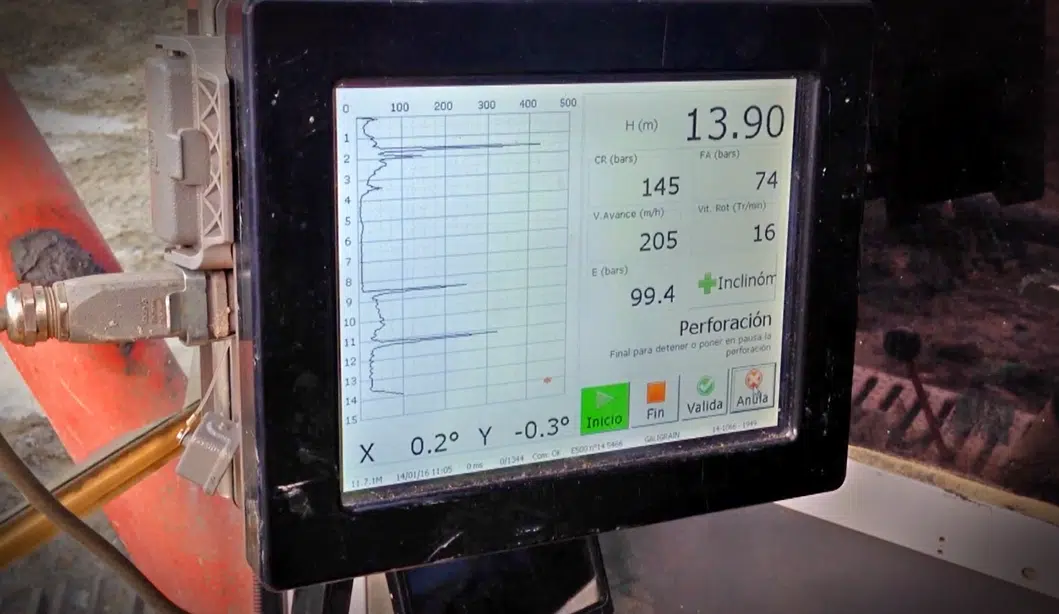

Additionally, a real-time monitoring system is connected to the rig sensors to track installation parameters, including drilling (rotary and crowd pressure, depth, rotation speed, and torque) and injection parameters (material quantity, pumping pressure). All of these parameters are displayed on a screen in the operator’s cabin, providing real-time data to ensure that the CMCs are installed precisely according to the design, optimizing their performance.

3. Post Construction

Once the CMC rigid inclusions are in place, we need to confirm they work as expected.

To validate the design of CMC, we conduct a static load test on an isolated inclusion. This test checks the bearing capacity and deformation of the Soil/CMC system under a compressive vertical load. In simpler terms, the test simulates the amount of weight the soil and CMC columns can support to ensure that the foundation can handle the intended load and provide long-term stability.