Technique

Bi-modulus column, a combination of two Menard techniques. The bi-modulus column technique, developed in the early 2000s, consists in topping Controlled Modulus Columns with a compacted granular material. In 2009, Menard drew up a specification and had it approved by independent technical third party. To date, Menard has successfully carried out numerous projects using the method.

About BMC

Bi-modulus columns are particularly effective in cases of deep cut-off, to avoid unwanted moments in slabs on backfill or in a seismic zone. All these elements have generated exponential growth in the use of the technique since it was developed.

Application

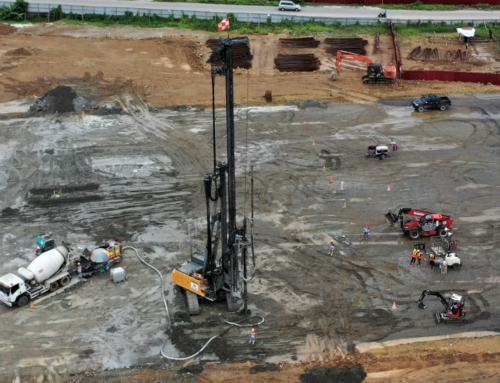

Controlled Modulus Columns are first installed with concrete stopping at least 1 metre above the bi-modulus interface level in order to ensure continuity. Following an initial curing period, there is a window of several hours during which the granular top is installed. It is formed by a stone column interpenetrated into the Controlled Modulus Columns head with a height of at least 50 cm over the top of the Controlled Modulus Columns.

Advantages

Bi-Modulus Columns (BMC) are vertical ground improvement elements composed of a rigid inclusion topped with a compacted granular column. BMC combine the advantages of Stone Columns and Controlled Modulus Columns™ (CMC), so the upper soil is not over-stiffened and is more compliant in areas with high seismicity, the thickness of the Load Transfer Platform (LTP) required for rigid inclusions is reduced, and there is no risk of column buckling or bulging in deeper weak soils. The use of BMC creates a more robust system — the upper granular part improving the load transfer mechanism and stress distribution from the structure or building to the rigid inclusion. This cost-effective technique optimizes the thickness of the LTP between the structure and inclusions.